Strive for continuous improvement,

Refining our competences,

To achieve the highest production quality

And minimize wastes

***

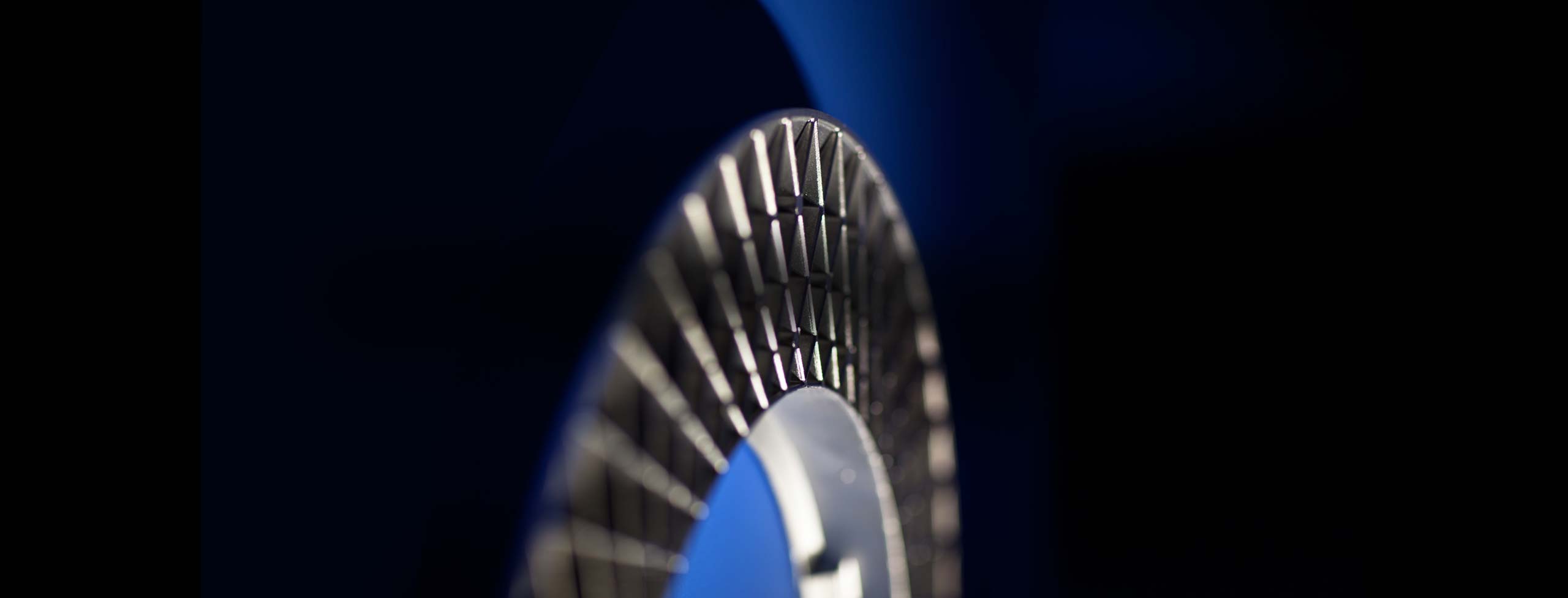

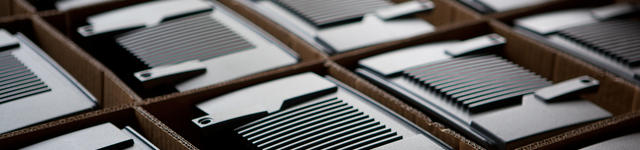

Since 1947 we design and manufacture molds

and produce die castings made of aluminium and zinc alloys

Open-mindedness, experience and competence of our people have allowed us to implement in time all technological innovations of the industry.

Reduced leadtime

italpres takes care of the production of die casting parts from the co-design, the development and manufacturing of the required equipment for casting, to the finishing and packaging, thus obtaining a significant reduction of leadtimes.

One responsible

With all required production departments available internally, italpres is the single point of contact for the customer. A remarkable advantage in terms of communication and essential in preventing misunderstandings between customer and suppliers, but also key to the utmost confidential treatment of all sensitive project data.

Technical support

With its qualified staff, highly experienced in the field of die casting, italpres assists its customers in designing and engineering both the parts to be produced by die casting processes, as well as the required equipment for molding and auxiliary operations.

italpres aluminium

The exclusive use of certified aluminium ensures better product quality.

In addition to controls made before delivery of raw materials, italpres performs internal instrumental checks to ensure no radioactive elements contaminate its plants and products.

Mold production for aluminium die casting

- Mold production for aluminium die casting

- Mold production for aluminium die casting in Italy

- Mold manufacturing for aluminium die casting

- Mold manufacturing for aluminium die casting in Italy

- Mold designing for aluminium die casting

- Mold designing for aluminium die casting in Italy

- Mold co-designing for aluminium die casting

- Mold co-designing for aluminium die casting in Italy

- Mold engineering for aluminium die casting

- Mold engineering for aluminium die casting in Italy

- Mold co-engineering for aluminium die casting

- Mold co-engineering for aluminium die casting in Italy

Die-cast aluminium die casting

- Die-cast aluminium die casting

- Die-cast aluminium anodizing

- Die-cast aluminium molding

- Die-cast aluminium ignition molding

- Production of die-cast aluminium articles

- Production of die-cast aluminium components

- Aluminium alloy and die-cast zinc die casting

- Aluminium alloy anodizing

- Aluminium alloy and die-cast zinc molding

- Aluminium alloy and die-cast zinc ignition molding

- Production of aluminium alloy and die-cast zinc articles

- Production of aluminium alloy and die-cast zinc components

- Die-cast aluminium

Die-cast aluminium alloy die casting

- Die-cast aluminium alloy die casting

- Die-cast aluminium alloy anodizing

- Die-cast aluminium alloy molding

- Die-cast aluminium alloy ignition molding

- Production of aluminium alloy die-cast articles

- Production of aluminium alloy die-cast components

- Die-cast light aluminium alloy die casting

- Die-cast light aluminium alloy anodizing

- Die-cast light aluminium alloy molding

- Die-cast light aluminium alloy ignition molding

- Production of light aluminium alloy die-cast articles

Mechanic workshop for the production of die-cast aluminium articles

- Mechanic workshop for the production of die-cast aluminium articles

- Mass production of die-cast aluminium articles

- Mechanic high-precision production of die-cast aluminium articles

- Certified production of die-cast aluminium articles

- Italian die-cast aluminium articles

- Mechanic workshop for the production of die-cast aluminium components

- Mass production of die-cast aluminium components

- Mechanic high-precision production of die-cast aluminium components

- Certified production of die-cast aluminium components

- Italian die-cast aluminium components

- Mechanic workshop for the production of die-cast aluminium products

- Mass production of die-cast aluminium products

- Mechanic high-precision production of die-cast aluminium products

- Certified production of die-cast aluminium products

- Italian die-cast aluminium products

- Production of light aluminium alloy die-cast components