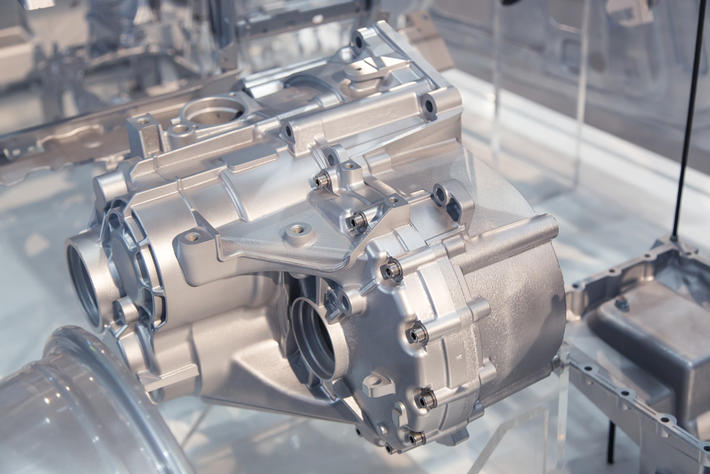

More efficiency in aluminum die casting with micro spray lubrications

The innovative lubrication technologies, widespread and distributed also in Italy, guarantee the optimal lubrication of the die-casting tool using minimum quantities of release agent.

The avant-garde of new sprays for lubrication in aluminum die casting

The thermoregulation and lubrication of the mold are the few phases of the aluminum die casting process where it is still possible to obtain savings and better efficiency. Today every foundry is able to achieve effective lubrication, but is this lubrication also efficient? Effectiveness indicates the ability to achieve the set goal, while efficiency indicates the ability to achieve it using as few resources as possible. Regarding the lubrication of the tool, the new release agents (oils or concentrates) are changing the philosophy of lubrication: while in the past lubrication was used to cool the surface of the mold, today it is only used to create the separation film between the mold and the jet.

Consequently, the thermoregulation of the mold must be optimized as much as possible: the heat removed in the past by the water spraying, must now be removed by the thermoregulation. In addition to this, the discriminating factor is the technology used to apply these products: to obtain the best results, the release agents must be micro-dosed. The accuracy and repeatability of micro-lubrication are crucial, and can only be achieved by using suitable technologies. The new spray technologies can achieve the goal in different ways that adapt to the different needs of foundries, with long-lasting production or frequent mold changes. The amount of release agent sprayed per nozzle can be reduced down to 0.01 ml. Furthermore, once the desired quantity has been set, this will remain stable and constant and independent of external factors such as the pressure of the release agent or the air pressure.

Multiple objectives can be achieved:

- - shorter cycle time (in some applications, it is theoretically possible to achieve a spraying time of 1 second)

- - reduction of the release agent (going from a few dozen to a few units of concentrated release agent)

- - reduction of water consumption (only necessary if thermoregulation cannot be effective in some areas of the mold)

- - reduction of air consumption (thanks to the shorter spraying time and the fact that it is not necessary to dry the matrix)

- - cancellation or reduction of water disposal costs (water is not used or less is used during spraying)

- - longer life and greater availability of the mold (thanks to the reduction of thermal shocks)

- - better quality of the castings and reduction of waste (thanks to the more homogeneous temperature of the mold and the reduction of porosity caused by water)

Source: A&L Aluminium Alloys Pressure Diecasting Foundry Tecchniques