Die-cast aluminium component painting is typically final finishing operation of a die-cast article. The customer often asks the foundry directly that also deals with other finishing operations to optimise production efficiency.

Aluminium is a silver grey metal that is very ductile, malleable and lightweight but also durable. It can be easily machined and moulded into any shape and can also be painted.

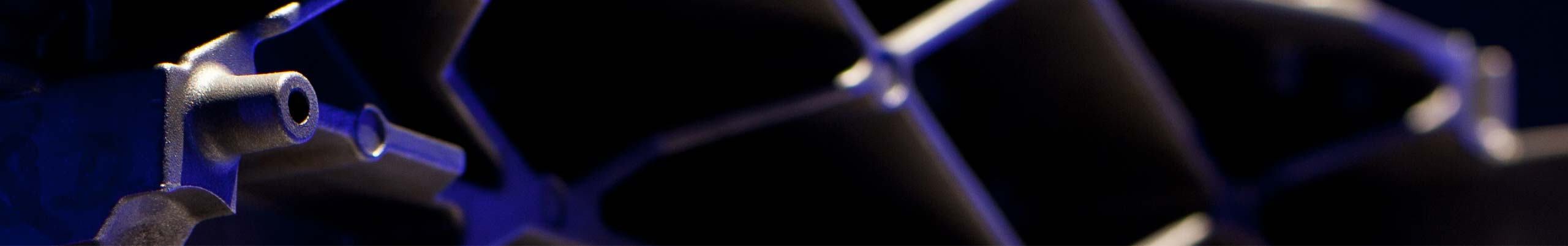

The die-cast aluminium component painting proposed by italpres, techincally speaking, is a powder coating, a surface coating process that can have both decorative and provide protection against corrosion or agents that could compromise its properties.

The process consists of first covering the die-cast parts with a synthetic powder paint, then the pieces are placed in a furnace in which, thanks to the temperature, the powder melts and then polymerises into a coloured adhesive film that perfectly covers the entire surface of the pieces.

The quality of the result depends on how much the die-cast piece has previously been prepared for painting (deburring, scrubbing or tumbling etc.). Powder coating is undoubtedly the best in terms of adhesion, durability and strength, as well as mechanical stresses, compared to liquid paint, however it is not comparable in terms glossiness to paint.