Aluminium casting, also known as "die casting", is a process developed in the United States in the mid-19th century whereby a molten metal, or alloy, is injected at high pressure into a metal mould. Once the injected metal has solidified, the metal mould is opened and the resulting part is removed.

How does the casting process take place and what do we mean by a shell?

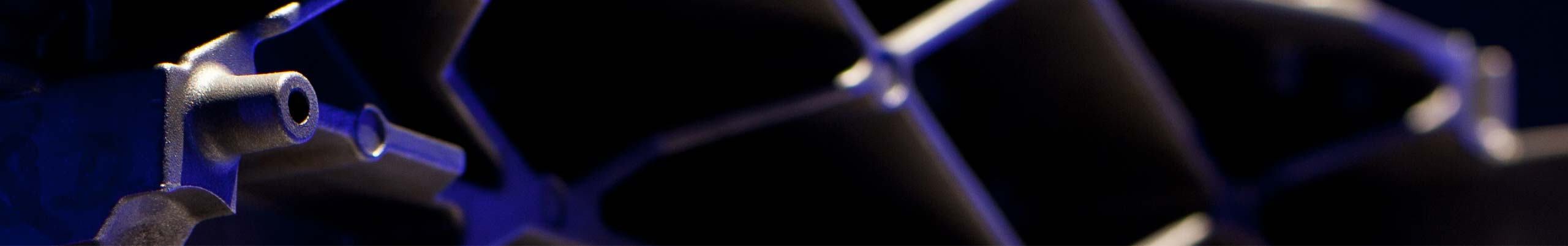

The shell is a mould, mainly made of steel, into which the molten aluminium is poured directly. It is mounted on presses called 'clamshells'.

After the aluminium has been melted in the special melting furnaces, it is removed and passed on to the casting process, which is carried out through the casting channel, using gravity to fill the figure. Casting can be done automatically or manually.

Once the metal has solidified, all that remains is to open the shell and extract the aluminium.

The advantages of shell castings are considerable, we have a lower wall thickness and this inevitably reduces the weight, we also get a better surface finish. In addition, with shell castings, the quality is much better than with sand castings as the metal takes less time to solidify.

Clamshell castings are ideal for medium-sized batches and guarantee excellent precision, surface finish and high standardisation.

The aluminium casting process

The aluminium casting process is automated and computerised, thus lending itself to high productivity. Constant control of the casting process ensures the best possible quality of the castings and maximises the production efficiency of its plants.

Thanks to the high technological and quality standards achieved today by the equipment and machinery, the parts produced by die casting ensure minimum dimensional tolerances and better surface finishes than other foundry processes.

Thanks to modern die-casting plants for aluminium and zinc alloy parts with capacities from 100 to 1400 tons, italpres is able to produce high-tech items with weights ranging from 4 grams to 15 kilos, in small, medium and large series.