Die-cast aluminium shotblasting is almost always an intermediate finishing process of an article that uses erosion to remove the upper surface of the workpiece thanks to the abrasion obtained from the blast of sand and air. Sandblasting of aluminium products is the most effective technique for the surface preparation treatment of die-cast products before they undergo painting or the application of a protective layer against corrosion.

Sandblasting methods can vary, in particular they can be "wet" or "dry", however, in this sector, the dry method is the most widespread and preferable one, both for the issue of corrosion and the quality of the final result. The die-cast aluminium shotblasting is mainly made by propelling steel microspheres against the surface to be treated to ensure maximum homogeneity and no surface defects.

There are 4 different sandblasting grades, depending on the sandblasting result to be obtained, from the finest called "white metal" (Sa3, according to ISO8501-1), to "almost white metal blasting" (Sa2.5), "commercial blasting" (Sa2), up to "coarse sandblasting" (Sa1).

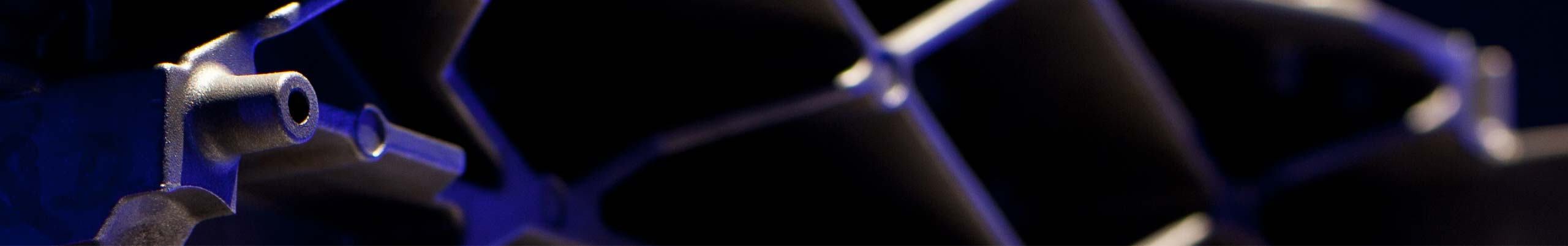

Die-cast aluminium shotblasting is a treatment particularly suitable for die-cast articles in the "automotive sector". Since aluminium is less resistant than iron and therefore more susceptible to deformation and surface damage due to possible errors in the treatment, care should be taken in the treatment of aluminium sandblasting and entrusted to skilled and qualified technical personnel, such as those working in the dedicated department at Italpres.

Another variable to consider in this process is the "sandblasting profile", i.e. the degree of surface roughness to be achieved. The roughness depends directly on the granulometry, the quality of the abrasive and the initial condition of the surface to be treated.