Die casting, otherwise defined as "casting under pressure in permanent mold", is a process developed in the United States in the mid '800, by which a molten metal, or an alloy, is injected at high pressure into a metal mold. Once the injected metal solidified, the mold is opened and the obtained metal piece extracted.

The mold

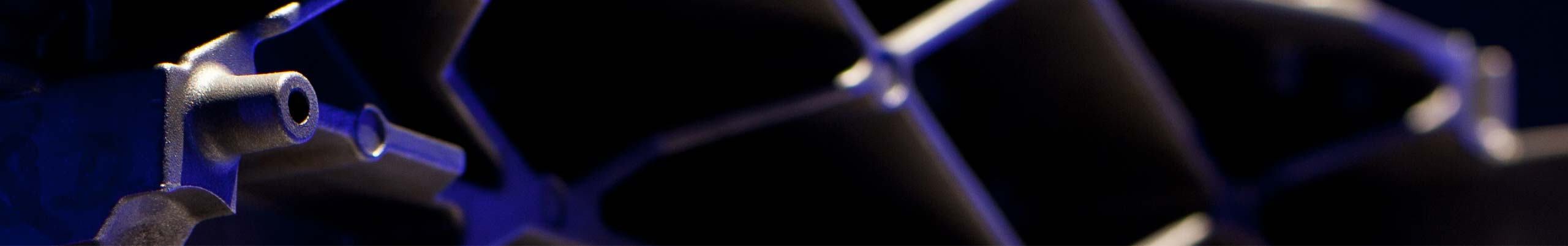

The mold, or die, typically made of steel, is composed of two halves to allow the extraction of the casting, once this has been properly formed with the mold closed. The materials of which the various parts of the mold are made up, are always metals with melting points higher than the injected material, generally aluminum alloys, magnesium or zinc.

The casting process

The injection pressure of the molten material can vary depending on the weight of the piece to be obtained, but also the type of material to be melted employed. It is important that the pressure is then maintained constant for the whole duration of the melting process, that is, up to the solidification of the piece, which is supported by an internal cooling circuit to the mold in which is entered the liquid. Hydraulic presses ensure in the meantime the perfect and complete closing of the mold: once solidified the piece, the presses enable the two die halfs to be opened so that the workpiece can be extracted.

The die casting process is highly automatable, for this reason it lends itself to high productivity. Thanks to high technology and quality standards achieved today by equipment and machinery, the parts produced by casting ensure minimal tolerances and surface finishes better than others foundry processes.

The design of the die casting process

In any case, already in the design phase of the casting process, the variables on which to work are pressure and temperature. These two parameters are in fact those on which on one hand the quality of the castings, on the other hand productivity depend. High pressures favor the filling of the molds in a shorter time, and thus realizing a greater productivity, conversely, lower pressures allow to avoid filling defects caused by the speed input and better preserve the mold from which the piece is obtained. It should also be considered that at high pressures it is easier to avoid the formation of gas backwash in the casting.

A similar argument can be made for the management of the temperature of the molten metal, which can not be too low, otherwise the casting would solidificate before the end of the injection, or the mold would not fill properly, but not too high either, because this affects cooling rates of the pieces, and therefore productivity.

Although the values of pressure and temperature are estimable at the beginning of the design process of the mold, the variables involved are so numerous that it always ends up with having to performe actual casting trials to determine these values empirically.

In recent years the use of vacuum systems is more and more widespread, a construction technique of the mold which creates a strong vacuum, thus increasing the pressure inside the mold and improving the filling of the pieces at equal pressure.

Hot chamber and cold chamber

Die casting can be divided into two broad categories:

- Hot chamber die casting, when the furnace of molten metal is placed in a furnace

- Cold chamber die casting, if the oven is a simple cavity not at controlled temperature