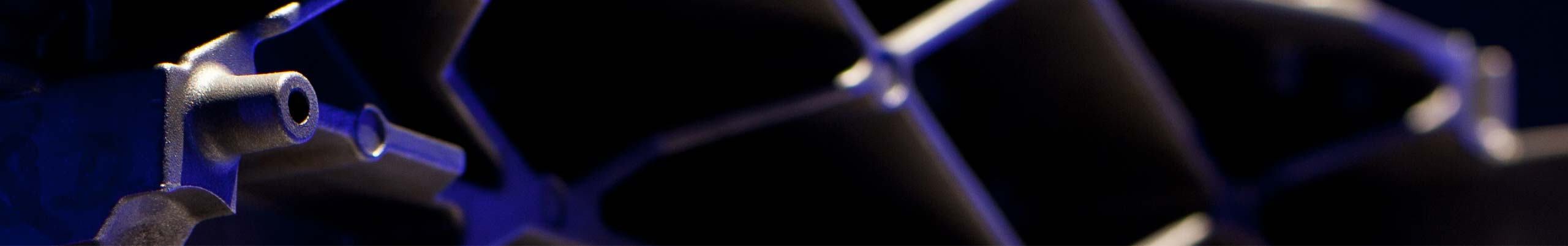

Die-cast aluminium anodizing is an electrochemical process through which a layer is created on the metal surface to protect it from corrosive agents.

In addition to improving resistance to corrosion, aluminium anodising is typically used to increase surface hardness and as a result the resistance to wear and abrasion, but also to provide better thermal insulation of the piece or enhance other features such as bonding or painting. In other cases it may even be simply a question of appearance.

Die-cast aluminium anodizing is a non-spontaneous electrochemical process by which a protective oxide layer forms on the surface of the treated metal and protects it from corrosion.

The anodising process is mainly used for aluminium. The material undergoes an actual surface transformation: the bare metal reacts with oxygen that develops during the electroplating process and forms aluminium oxide or alumina. Similar procedures are available and used also for titanium, zinc, magnesium, zirconium, hafnium, niobium and tantalum.

What exactly is die-cast aluminium anodization?

When an electric current supplied by an external electrical circuit (cathode) is circulated through an electrolytic cell in which the aluminium immersed in an aqueous solution acts as an anode (positive pole), the negative ions (anions) formed by dissociation, mainly of the oxygen, migrate, by attraction between the opposing charges, toward the positive anode, aluminium, to which they gave the electric charges they are carrying. The layer deposited on the surface is a layer of aluminium oxide formed by an electrolytic process.

Basically, the anodised aluminium surface is characterised by an electrochemical treatment that covers it with a thin oxide layer that protects it from corrosion.