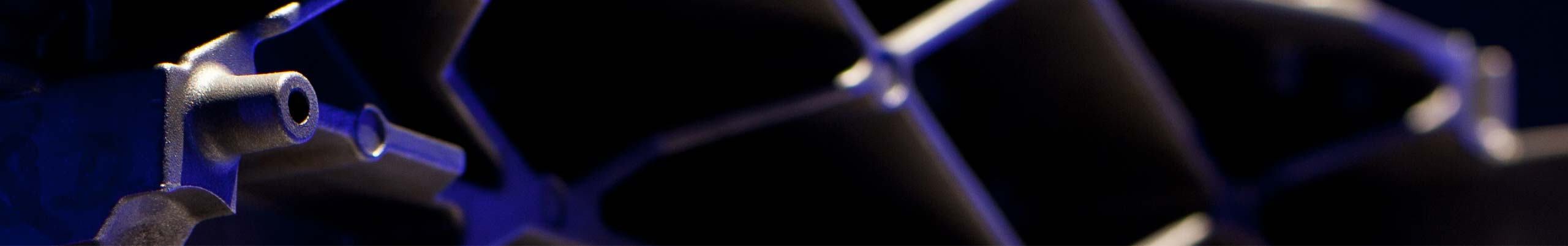

Italpres' decision to have its own internal construction department for moulds for aluminium die casting is a guarantee of promptness in resolving any problems that might affect the equipment once it has reached the die-casting stage.

The construction department for moulds for aluminium die casting is also a production strategy in order to have control of the production process. A decision that prevents time from being wasted and potential misunderstandings, and at the same time provides the customer with a reliable, single interface able to handle the entire process at a more competitive price, in proportion to the technology used.

Italpres, since its establishment some 70 years ago, has had the idea of a department with state-of-the-art machinery that is constantly updated or replaced in light of technological innovations.

The department also has dedicated, highly qualified technical personnel who undergo continuous training. Today, there is a range of equipment available, many of which is technologically complex. Italpres can also just perform the die casting of an article if the customer already has the relevant equipment, as well as being able, if necessary, to work with third-party equipment.

What is needed for the production of moulds for die casting?

Steel is required for the production, which has melting points higher than the injected material, aluminium. Some parts of the mould can be made from different types of steel in order to favour some processes useful in the production of the mould itself.

Production takes place directly within the Italpres production plant at Lumezzane, in the technologically advanced workshop equipped with milling machines, and other machinery that allow precise processing (in the order of hundredths of a millimetre) and that are based on technologies such as EDM.