The aluminum anodizing service: what is it and what it is used for

The anodization of aluminum is also known as "anodic oxidation" and is an irreversible electrochemical process by which a protective layer of aluminum oxide forms on the surface of the particular treated and protects it from corrosion. In other words, through this electrochemical process, a protective film is formed around the object. In aluminum, the anodizing service is particularly used, but it is also used for other elements such as titanium, zinc, magnesium, niobium, zirconium, hafnium, tantalum.

How anodizing of aluminum works

It is not a spontaneous process, the layer is not created independently. Aluminum must be reacted with oxygen in an electrodeposition process. The material undergoes a surface transformation: the bare metal reacts with oxygen and forms aluminum oxide, also known as alumina. There are two types of aluminum anodization: a thin one, a hard one. The first forms a layer between 5 and 20 microns, the second 20 to 30 microns. The harder the layer, the better the weather resistance. In fact, the lowest micron values are usually used for products intended for interiors without frequent manipulations, while those with more micron are intended for exposure to the aggressive urban or marine atmosphere because they have a reinforced layer.

The phases of the aluminum anodizing cycle

There are three phases of the aluminum anodizing service. The first is the preliminary one: various types of chemical and mechanical pre-treatments are carried out on the product, such as brushing, degreasing, pickling, satin finishing and neutralization. Afterwards, we proceed by the actual anodic oxidation process: the oxide film formed after the treatment is extremely porous, it can easily be stained because it tends to attract external elements. In case of coloring, it is possible to act in this moment, before fixing, which ensures the closing of the pores making the anodic glassy and impermeable layer, avoiding the loss of the possible dye and increasing resistance. At the end of the aluminum anodizing process, oiling is carried out, which eliminates the fixing dust.

What is the use of aluminum anodizing?

The purpose of the aluminum anodizing service is useful for:

- Improve corrosion resistance,

- Increase hardness,

- Increase resistance to wear and abrasion

- Ensure moderate thermal insulation.

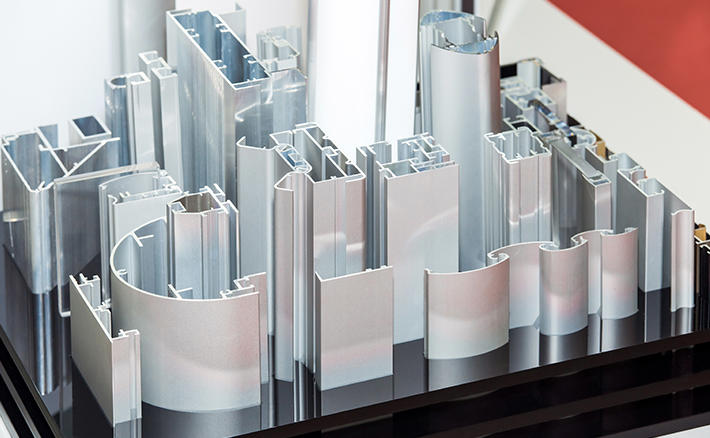

Moreover, it can be used as a pure aesthetic improvement of the aluminum surface generated by the die-casting process.