Articles in die-cast aluminium and construction molds: customer's questions

The optimization of productivity is the main objective of customer service of the company, offering a wide range of customizable solutions and the work of the technical team provides services and assistance.

What are the questions on which focuses primarily the attention of customers who contact the casting department?

''We are often asked the possibility of thickness and thin-walled die-casting alluminium items – answers Mr. Zani, one of the owners-we supply tolerances by making your data directly with the aluminum die casting process by avoiding where possible further change.''

italpres also assists clients in finding other suppliers to complement to the worker process that is done within the department of die-cast in Lumezzane.

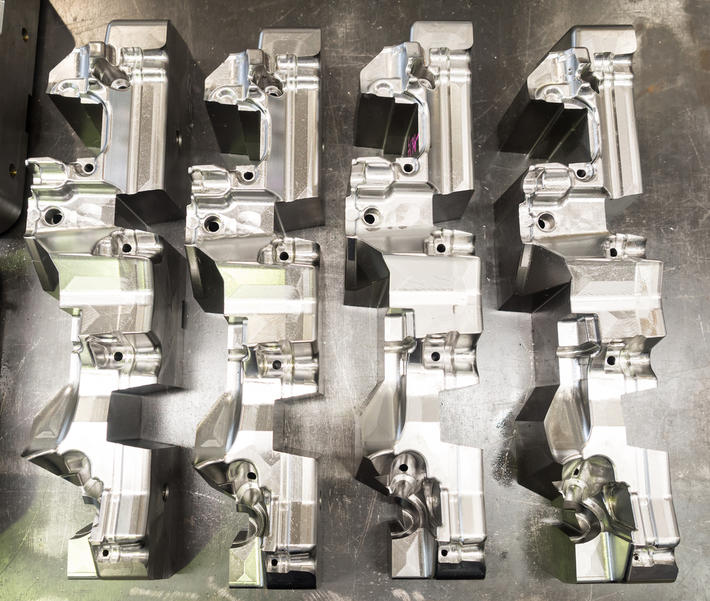

We design and manufacture moulds internally through a specialized technical department-continued Zani- while for processes and finishes die-cast aluminium item details, such as oxidation and chroming, we rely to companies with which we have been working for years and of which we know and appreciate experience and professionalism.

Basically, italpres guarantees a finished product dealing with all you need to provide a turnkey service, always at competitive prices. Another aspect that focuses the attention of the customer is the die casting process of the alluminium article.

In the planning phase of the process, the variables on which you work are pressure and temperature. These are the two parameters on which you play on the one hand, the quality of castings, the other side productivity. High pressure promotes the filling of molds in less time, and then you can achieve greater productivity, while low pressures help avoid filling defects caused by input rate and preserve the shape from which you obtain the piece.

In addition, the high pressure cast aluminum minimizes the formation of gas in undertows.