A bright future for aluminum diecasting in the automotive sector

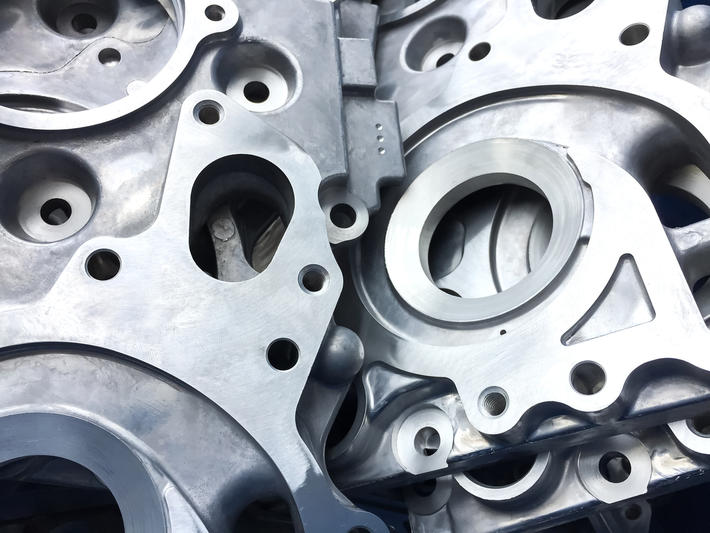

The shift of the automotive industry towards the production of electric vehicles is creating opportunities for aluminum die casting in new production areas.

Ever since Henry Ford introduced his groundbreaking production line more than a century ago, innovation has been a driving force in automotive manufacturing. And now the electric mobility revolution is once again bringing with it a radical rethinking of car manufacturing methods. Both incumbent and incoming car manufacturers are trying to simplify their production methods and save costs by reducing the size of assembly lines and making use of ever larger components.

The industry is also changing the materials used to produce cars. All this creates new and exciting opportunities for aluminum die casting in the automotive sector.

Although the automotive industry is currently limited by the lack of chip availability, the growth in interest in die casting solutions from around the world by automotive manufacturers is somewhat staggering. The automotive industry has always been one of the main drivers for the innovation of die casting. The current appetite for new investments is truly encouraging for our sector as a whole.

The types of bodywork: at the center of the change in the automotive and aluminum diecasting sector

Body concepts are the trending topic. Larger parts - such as an entire rear or front underbody - mean that a single aluminum diecast piece can replace up to 70 traditional components made of steel. This eliminates numerous assembly processes, can cut hundreds of robots off production lines and reduce factory footprint by up to 30%.

For the diecasting industry, innovating together with the automotive industry is essential. The automotive sector in fact needs complete solutions for integrated islands that include everything from the oven to the handling of parts. It needs bigger and more precise machines. And it needs global support to streamline production, plan workflow and integrate processes at plants around the world.

The increase in requests for aluminum diecasting projects

There has been an explosion of requests for projects and concept studies from the automotive sector.

Producing large aluminum castings, rather than joining the individual sheet metal components together, is a new skill set for many automotive manufacturers and their suppliers. For example, with larger machines, the foundry may require a new layout, different robots and new part handling processes.

Working together with customers to plan and implement every detail of the island as a complete solution for each specific use is essential for success. The support and training of operators are also essential. From an introduction to diecasting, to dedicated modules and advanced technological training on process optimization and mold design, these are fundamental paths to allow the automotive sector to grow with aluminum diecasting. All this can in fact bring operators up to speed quickly and help them refine and continually improve production.

Digitization as a central component for the increase of aluminum diecasting in the automotive sector

The propensity to invest must be guided by the dual objective of improving efficiency and sustainability. We know that greater digitalization can significantly improve the efficiency and profitability of production and reduce their environmental impact.

The goal is to achieve 0% waste, a 40% reduction in cycle time and 24/7 operation. Digitization unlocks all of this. Each step towards more connected and automated foundries is a step towards significant cost savings and more sustainable production.

However, sustainability has two sides. First of all, the impact of the investment. And secondly, the environmental impact during operation. The purpose of the automotive sector is to reduce the consumption of energy, waste and water in value chains. From an operational point of view, using recycled or primary aluminum extracted with renewable energy means that the castings can be carbon neutral, improving the ecological credentials of the finished vehicle.

It is a strategy that involves the entire supply chain. From suppliers to car manufacturers, auxiliary equipment manufacturers, system integrators and technicians building a new plant, it is essential to work together to achieve the best results for the application, for the environment and to extend the useful life of the cars.

Source: A&L Aluminum Alloys Pressure Diecasting Foundry Tecniques